These Common Renovation Mistakes You Might Need to Avoid in 2026

Introduction

Home renovations promise comfort, efficiency, and pride of place—but only when plans, budgets, and execution align. In 2026, material prices are steadier than recent peaks, yet labor shortages, permit backlogs, and design fads still create risk. The smartest projects blend rigorous planning with flexible management and sober design choices that stand up to time. This article shows where projects commonly go sideways and offers practical tools for avoiding delays, overruns, and regrets.

Outline

– Section 1: Costly Missteps—how hidden issues, scope creep, and permit errors derail timelines

– Section 2: Plans, Budgets, and Buffers—estimating methods, contingencies, and cash-flow control

– Section 3: Design for the Decade—durability, adaptability, and resale-aware choices

– Section 4: Renovation Trends to Watch in 2026—electrification, resilient materials, flexible spaces

– Section 5: From Permit to Punch List—contracts, inspections, and a step-by-step roadmap

Costly Missteps: The Hidden Traps in Home Renovations

Every renovation holds “unknowns” behind walls and under floors. The most common trap is underestimating the cost and time of resolving them: outdated wiring that can’t handle modern loads, plumbing that fails a pressure test, or structural members weakened by moisture. Industry reports from recent years show average cost overruns frequently land in the 10–20% range, and surprises are a leading cause. If you don’t set aside money and calendar space for discovery, you’ll pay in rush fees and compromised choices later.

Scope creep is another quiet budget-eater. Add a tile accent here, bump a wall there, and suddenly you’re juggling extra demolition, backorders, and additional inspections. A practical countermeasure is a change-order threshold: any change that adds cost or time must be documented, priced, approved, and scheduled before work continues. That keeps spontaneous “might as well” ideas from snowballing into chaos. Also, avoid deferring boring maintenance for shiny finishes. Fixing drainage, sealing the building envelope, or upgrading the panel rarely gets social-media love, but these improvements protect everything you do see.

Permits and sequencing matter as much as finishes. Missing a structural permit or an energy-compliance detail can cause multiweek delays. Build your plan around inspections: rough-in electrical and plumbing, framing, insulation, and final sign-offs each need room in the schedule. Small efficiencies help: ordering long-lead items (e.g., windows) before demolition, renting debris bins in phases to avoid overflow fees, and grouping noisy work to minimize neighbor complaints and potential stoppages. An overview of common renovation mistakes discussed for 2026, focusing on planning decisions, budgeting challenges, and long-term design choices.

Watch for these early warning signs that a project is sliding:

– Estimates that arrive without line items or assumptions

– “We’ll figure it out on site” answers to code questions

– Multiple allowances with vague product descriptions

– No contingency in the budget or calendar

Each signal points to risk that can and should be addressed before demolition begins.

Plans, Budgets, and Buffers: Avoiding Financial Drift

A strong plan is a financial tool, not just a drawing. Begin with a written scope that defines what is included, what is excluded, and what is optional. Require line-item estimates grouped by trade—demolition, framing, electrical, plumbing, HVAC, cabinetry, finishes—so you can compare bids apples-to-apples and cut or add with precision. Every allowance (for tile, fixtures, or hardware) should list a unit price, quantity, and a realistic grade; this prevents “sticker shock” when you discover that the allowance covers builder-basic, not the look you expected.

Budgeting for 2026 should assume volatility pockets. While many materials have normalized compared to the sharp spikes of early 2020s, regional swings are still common. A prudent contingency ranges from 10% for light cosmetic updates to 20% for structural or system-heavy work. Cash flow matters too: align payment milestones to delivered value, not just time. For example, schedule payments around inspections passed and materials on site, with a modest retainage (often 5–10%) held until punch-list completion. This structure incentivizes progress and protects your finish quality.

Compare estimating methods and their trade-offs:

– Square-foot pricing: quick, but hides complexity and can mislead on small or intricate rooms

– Assembly-based pricing: counts parts (studs, sheets, fixtures), better for accuracy, requires detail

– Hybrid approach: square-foot for early framing and drywall, assemblies for mechanicals and finishes

Whichever you choose, insist on written assumptions—ceiling height, substrate condition, lead times—so you can adjust fairly if facts change.

Forecast soft costs early: design fees, engineering, permits, waste hauling, temporary utilities, and site protection commonly add 10–15% to the bill. Consider time risk as well: inspections can add days; backordered fixtures may pause tile work; weather can stall exterior phases. A schedule buffer of 15–25% keeps one late delivery from derailing everything. Finally, revisit the budget at each milestone. A 15-minute review after rough-in can capture minor shifts before they pile up into a major overrun.

Design for the Decade: Choices That Age Well

Trends come and go, but durability, safety, and adaptability hold value. Think of design as a 10-year decision: will this layout still work if your family grows, you host more often, or you need accessibility features? Timeless doesn’t mean dull. It means materials and forms selected for resilience and easy refresh. For example, choose a neutral, repairable primary surface (flooring, countertops), and layer personality through replaceable elements—paint, hardware, and textiles.

Longevity involves more than finishes. Electrical capacity should anticipate future loads—electric vehicles, induction cooking, or heat pump systems. Smart water shutoff valves can prevent costly leaks, and better insulation plus air sealing can reduce heating and cooling needs by double-digit percentages in many climates. When you select windows, consider not only U-factor and solar heat gain but also serviceability: can the weatherstripping be replaced, and are parts widely available?

Design also has a cost-of-ownership dimension. A textured porcelain tile may hide dirt and resist scratches better than a highly polished surface; a factory-finished wood floor can be easier to maintain than a site-finished option subject to jobsite humidity swings. For wet areas, prioritize waterproofing systems with documented test data and follow manufacturer sequencing to the letter. And remember how people actually live: drop zones at entries, charging stations where devices accumulate, and lighting layers that support cooking, reading, and relaxing. An overview of common renovation mistakes discussed for 2026, focusing on planning decisions, budgeting challenges, and long-term design choices.

To pressure-test choices, try these quick checks:

– Replaceability: if a piece chips, can you source a match next year?

– Cleaning reality: who cleans it and with what products?

– Code and safety: will evolving energy or ventilation rules force a redo?

– Resale lens: would a broad audience see this as a plus, neutral, or minus?

Using these prompts shifts decisions from impulse to intention—exactly where lasting value is forged.

Renovation Trends to Watch in 2026

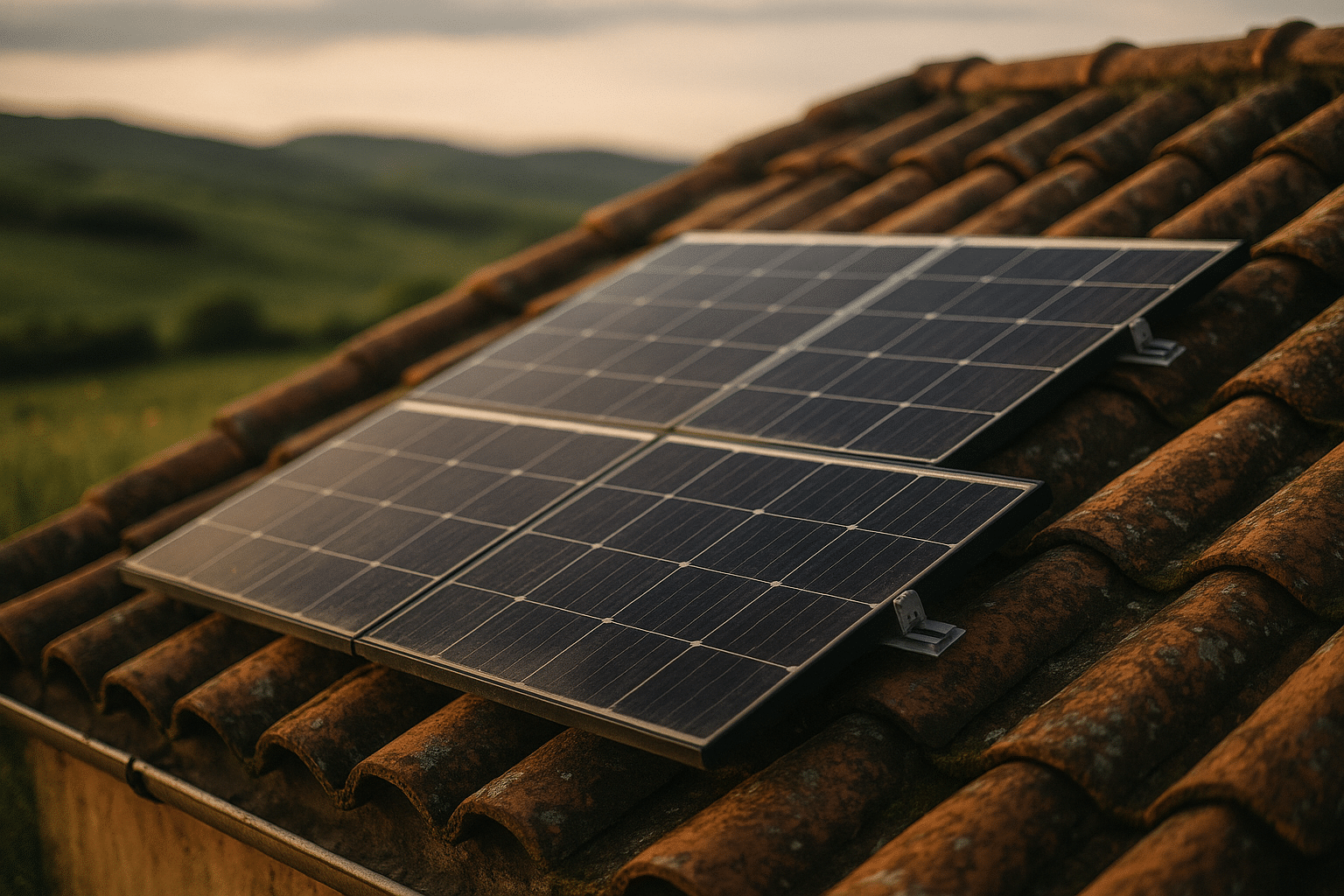

Several 2026 trends look less like passing fashions and more like structural shifts in how homes function. Electrification continues to expand: panel upgrades with space for future circuits, high-efficiency heating and cooling, and induction-ready wiring are becoming standard in forward-looking remodels. These changes often pair with tighter building envelopes, improved ventilation with heat recovery where appropriate, and an emphasis on moisture control to protect indoor air quality.

Resilience and sustainability are converging. Expect more recycled-content surfaces, regionally sourced materials to reduce transport emissions, and design strategies that manage heat and water: deeper roof overhangs, shaded glazing on sun-heavy facades, and robust exterior drainage. Biophilic touches—daylight through well-placed windows or solar tubes, views to greenery, and natural textures—help spaces feel calmer and may reduce reliance on artificial lighting during the day. Flexible rooms are also rising: a guest room with acoustic treatment becomes a video-conference office; a dining area with concealed storage doubles as a craft or homework zone.

Data-informed energy choices are maturing. Homeowners increasingly demand utility-bill modeling before committing to upgrades. While savings vary by climate and usage, tighter envelopes plus right-sized mechanicals often cut heating and cooling loads meaningfully. Leak detection and shutoff tech can limit water damage, and smart thermostats help smooth demand. Yet discipline still wins over gadgets: good flashing beats a fancy app when the sky opens. Balance wishlist items with code compliance, local climate realities, and maintenance capacity.

Procurement is becoming more strategic, too. Long-lead items—custom windows, specialty tile, high-efficiency equipment—should be ordered early and stored securely. Builders are standardizing certain components to reduce waste and simplify service later. Consider keeping a small attic of spare materials: extra tiles, a length of baseboard, a box of flooring. It’s a low-cost hedge against future repairs that keeps your finishes consistent years down the line.

From Permit to Punch List: Managing Quality and Risk (Your 2026 Roadmap)

Great results depend on steady, documented progress. Start with the right contract structure. Fixed-price agreements work well for clearly defined scopes, while cost-plus contracts can suit evolving designs if they include caps, transparent time sheets, and regular reconciliation. Build a milestone map tied to inspections and deliverables: framing complete and approved, rough-in mechanicals signed off, insulation dense-packed and inspected, drywall hung and taped, cabinets installed, tile grouted, and final walkthrough scheduled.

Quality control thrives on checklists. Before each wall is closed, confirm photos of wiring, plumbing, blocking, and air-sealing details are archived. Maintain a shared log for questions and decisions—model numbers, finish sheens, grout colors—so the site team and homeowners stay aligned. A weekly 20-minute stand-up meeting can eliminate days of confusion. For risk management, verify insurance certificates, lien releases with each payment, and site safety practices. Simple measures—cord covers, dust containment, negative air for sanding—protect both workers and your home.

Permitting is a partnership with your local authority. Respect sequencing and keep submittals tidy: stamped plans where required, product data sheets, and energy or ventilation documentation. If an inspector flags an issue, treat it as a free peer review rather than a setback. Build a buffer for re-inspections and maintain a calm schedule—crews perform better without constant crisis mode. An overview of common renovation mistakes discussed for 2026, focusing on planning decisions, budgeting challenges, and long-term design choices.

Finally, land the plane with a clean handoff. Conduct a room-by-room punch walk, tag items with painter’s tape, and convert those tags into a written list with target dates. Collect manuals, warranties, and care instructions, and store a digital copy. Keep a 30-day and 11-month check-in on the calendar to catch seasonal shifts and warranty items. This disciplined finish saves callbacks, protects your investment, and leaves you with a home that feels—and functions—ready for the decade ahead.