Learning About Prefabricated Homes for Seniors

Outline:

1) Housing basics and definitions

2) Home features for safety and comfort

3) Structure and construction process

4) Costs, financing, and long‑term value

5) Planning considerations and next steps

Introduction:

Age-friendly housing is becoming a central topic as longevity rises and families look for practical ways to support independence. Prefabricated options are drawing attention because they pair controlled factory construction with customizable layouts geared for safety and comfort. For seniors and caregivers, the goal is simple: a home that makes everyday life easier while staying adaptable as needs change. The following sections move from fundamentals to detailed planning so readers can compare options with confidence.

Housing Basics: Getting Oriented

Before comparing floor plans or finishes, it helps to define terms and understand how prefabrication works. In general, a home is built in a factory as modules or panels, then transported and assembled on a prepared site. A modular home typically follows the same local building codes as a site-built home, while other prefabricated formats may follow separate standards; the right choice depends on jurisdiction, climate, and personal goals. What people usually want to know first is straightforward: safety, cost, speed, code compliance, and long-term upkeep.

Key concepts to ground your search include:

– Prefabrication spectrum: panelized (wall/roof sections assembled on-site), modular (three-dimensional boxes joined on-site), and other factory-built formats

– Code alignment: confirm whether the home meets your local residential code or alternative standards recognized in your area

– Foundation types: slab, crawl space, or piers, chosen based on soil conditions, frost depth, and accessibility goals

– Timeline basics: factory work can take several weeks, followed by on-site assembly and utility hookups that often add additional weeks

– Quality control: indoor production reduces weather delays and enables consistent inspections at each station of the factory line

Compared with traditional construction, the controlled environment of a factory can reduce material waste and improve precision. For example, moisture-sensitive components are more consistently protected, which helps maintain the integrity of insulation and wood products. Delivery and crane set days are coordinated to minimize exposure; meanwhile, the site team handles foundation, utilities, and final sealing. The result can be a tighter building envelope, which supports energy efficiency and comfort when paired with appropriate ventilation. It’s also common to see single-level layouts prioritized for seniors, as they reduce fall risks and simplify daily routines. Taken together, these housing basics lay the groundwork for smart choices later, from features to financing.

Home Features: Safety, Comfort, and Everyday Ease

Features make the difference between “technically accessible” and truly livable. For many seniors, the most helpful upgrades work quietly in the background: better lighting, zero-step entries, and intuitive storage that keeps essentials within easy reach. A single-story plan with wider doorways and hallways supports mobility devices, while lever-style handles and rocker switches reduce hand strain. Non-slip flooring in kitchens, entries, and bathrooms lowers the chance of falls; contrasting colors at thresholds improve visibility for aging eyes.

Consider a feature checklist that supports independence without adding complexity:

– Entry and circulation: zero-step entry, 36-inch doors, 42-inch halls, and flush transitions between rooms

– Bath design: curbless shower with linear drain, grab bar backing in walls, a handheld showerhead, and a fold-down bench

– Lighting: layered lighting with motion sensors in halls and baths, under-cabinet task lights, and higher CRI bulbs for color clarity

– Surfaces and storage: non-glare finishes, D-shaped pulls, full-extension drawers, and pull-down shelves to reduce reaching

– Climate and air: balanced ventilation, quiet ductwork, and filtration sized to local air quality concerns

Comfort ties closely to acoustics and temperature stability. Thoughtful insulation and strategic door placement soften noise between living areas and bedrooms, making conversations easier to follow and rest more restorative. In parallel, right-sized heating and cooling, sealed ductwork, and effective shading keep temperatures even without constant adjustment. Smart-home devices can help—think door sensors that blink a light when someone arrives or a voice assistant that turns on lamps—yet the core design should work even when the power is out or a gadget fails. Materials also matter: easy-clean counters, resilient flooring that resists moisture, and cabinetry with durable edges all push maintenance lower. The aim is a home that quietly supports daily routines, accommodates changing mobility, and keeps choices simple without sacrificing dignity or comfort.

Construction and Materials: From Factory Floor to Finished Home

Understanding the build process demystifies delivery dates and quality expectations. How prefabricated homes for seniors are structured varies by system: volumetric modules arrive as nearly complete rooms, while panelized systems deliver wall and roof sections that are assembled on-site. In both cases, the factory typically cuts and labels components, installs insulation, runs wiring through chases, and preps openings for windows and doors. This controlled sequence limits weather exposure and enables repeatable checks for squareness, fastening schedules, and air sealing.

Material choices support durability and quiet, steady indoor conditions:

– Framing: engineered lumber or steel for straightness and load consistency, especially helpful for wider hallways and large door openings

– Enclosure: continuous exterior insulation to reduce thermal bridging, plus careful air sealing around penetrations

– Windows: double- or triple-pane units with low-e coatings matched to climate; daylight is vital, glare control is equally important

– Roofing and siding: durable finishes that tolerate sun and rain; look for products with documented maintenance schedules and repair methods

– Wet-area protection: tile or sheet systems with waterproof membranes, sloped floors, and accessible drain locations

On-site, a crane or lift sets modules or panels on a prepared foundation, followed by stitching—sealing, flashing, trim, and mechanical connections—to create a single, continuous weather barrier. A blower-door test, if available in your region, verifies air tightness; when combined with balanced ventilation, it can improve comfort and reduce drafts. Structural connections are engineered for local conditions such as snow loads, wind exposure, and seismic requirements, and tie-downs or hold-downs are specified to match. Many seniors prefer single-story spans, but when a second level is included, designers often plan a first-floor primary suite so stairs can be optional. Step by step, the process aims for reliability: parts measured once at design, again in the factory, and finally at assembly, with coordination notes traveling with each component so the finished home feels cohesive and solid.

Costs, Financing, and Long‑Term Value

Budget planning links dreams to practical next steps. All-in costs for prefabricated homes can vary widely by region, site conditions, and specification level; a rough range often spans from the lower hundreds to several hundred dollars per square foot when you include foundation, delivery, assembly, and finishes. Site work—driveway, utility runs, grading, and permits—can swing totals significantly, especially on sloped or remote lots. Financing also differs by format and local rules; some lenders treat modular homes similarly to site-built homes, while other factory-built formats may require different loan products or down payment terms.

To build a clear budget, break the plan into digestible parts:

– Land and site prep: surveying, soil tests, access for delivery vehicles, and foundation choice

– Factory scope: modules or panels, finishes, built-in cabinets, fixtures, and mechanical systems

– Transportation and set: delivery mileage, crane time, and on-site crew coordination

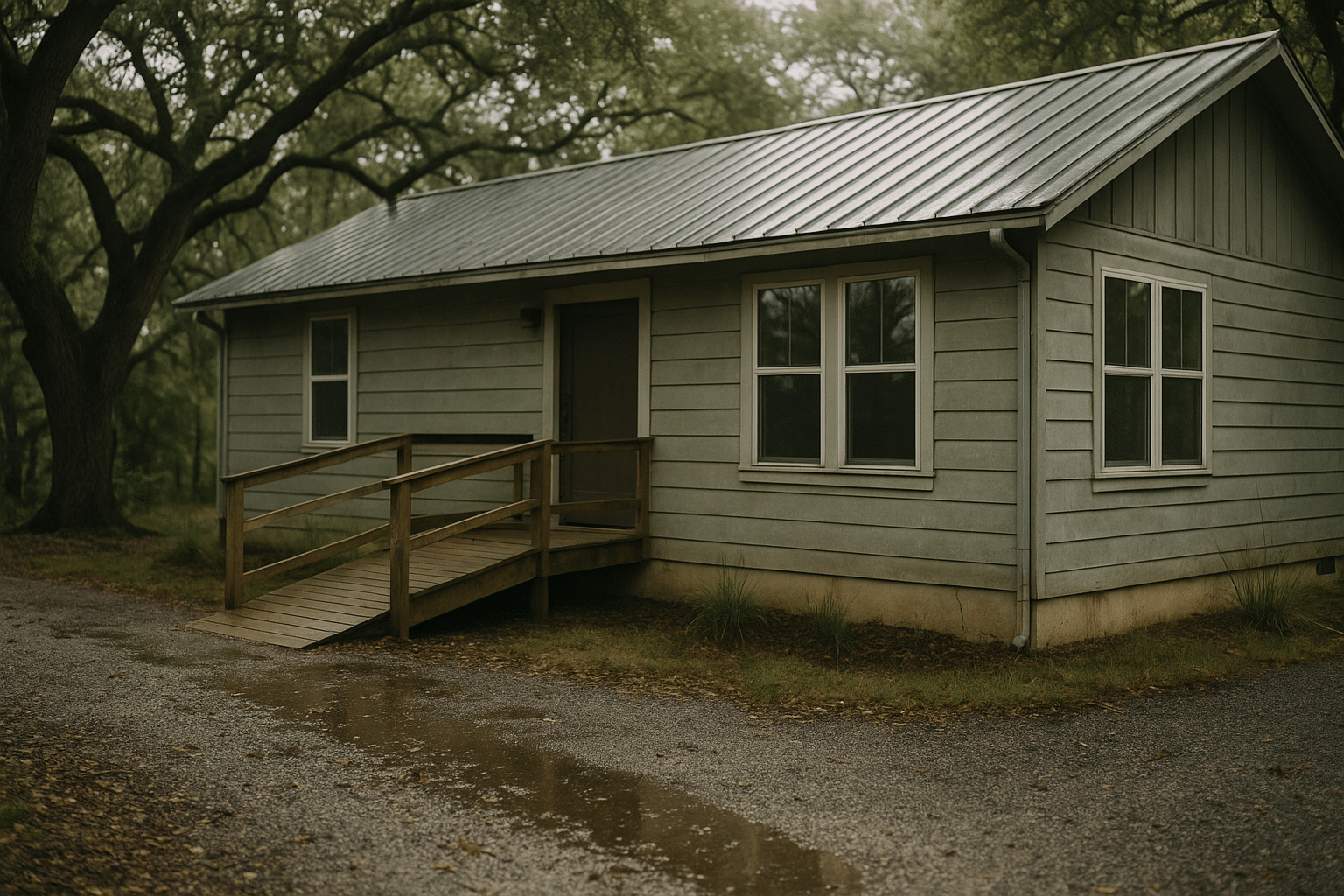

– Completion: roofing ties, siding seams, interior trim, deck or ramp, and final utility connections

– Contingency: a cushion (often 5–15%) to handle surprises without derailing decisions

Operational costs matter too. A tighter envelope, right-sized heating and cooling, and efficient lighting can trim monthly bills relative to older housing stock; the actual savings depend on climate, energy prices, and behavior. Maintenance is a long game: choose durable surfaces where traffic is high, plan for easy filter changes, and keep critical shutoffs accessible. Families sometimes compare these costs to assisted living or long-term care; while monthly fees in those settings can be substantial, a home still requires taxes, insurance, and upkeep, so run both scenarios with a realistic time horizon. Why clarity matters here is obvious: itemized scopes and written change-order rules prevent mid-project confusion, and a shared checklist helps the whole team—from family to builder—stay on the same page. With this framing, value becomes more than a price tag; it includes safety, independence, and the freedom to tailor space to evolving needs.

Planning Considerations, Location, and Next Steps

Strong planning smooths the path from idea to move-in. Start with local zoning and building department guidance: confirm allowable home types, setbacks, height limits, and any neighborhood design requirements. Site selection influences daily life as much as the floor plan—proximity to healthcare, grocery stores, parks, and transit can reduce driving dependence. Orientation and shading shape comfort and bills: southern sun may be welcome in winter, yet deep overhangs or exterior shades keep rooms cooler in summer. Access is paramount; a gentle slope from parking to the front door and space for a covered landing make arrivals safer in rain or snow.

Build a practical planning checklist that blends home and life logistics:

– Documentation: permits, utility applications, septic or sewer confirmations, and delivery route clearances

– Accessibility: ramp or zero-step entry, door and hall widths, turning circles, and future lift locations if stairs are present

– Services: reliable broadband for telehealth, backup power options for medical devices, and clear house numbers visible from the street

– Safety: illuminated paths, smoke and CO detectors, and a plan for periodic grab bar installation as needs evolve

– Support network: neighbors, family, and local services who can help with seasonal tasks like snow removal or storm prep

Care coordination belongs in the plan, too. If an in-home aide is part of the future, consider a small flex room near the primary suite that can toggle between office and guest use. Storage for mobility devices, a charging niche for scooters, and an easy place to stage deliveries turn minor hassles into non-issues. Keep documentation centralized: appliance manuals, filter sizes, paint codes, and a maintenance calendar reduce stress during busy moments. Communication with the builder benefits from short, frequent updates and a shared punch list; photographs at key stages create a record that helps with warranties and future adjustments.

Conclusion: A Clear Path to a Livable, Flexible Home

For seniors, caregivers, and families, prefabricated housing can offer a balanced mix of speed, quality control, and adaptability. By understanding the basics, choosing features that genuinely aid daily routines, grasping how construction flows, budgeting with precision, and mapping a practical plan, you turn an idea into a comfortable, future-friendly home. Keep decisions transparent, document them well, and give yourself room to adjust as needs change—the home will return the favor with safety, comfort, and ease.